The Fraunhofer joint project "HySecunda" aims to develop practical solutions for green hydrogen production in South Africa. Nine Fraunhofer Institutes and the Fraunhofer Academy are working together for three years to find optimized solutions for the production, storage and certification of green hydrogen.

South Africa has abundant renewable energy sources such as solar and wind that can be used to produce clean and sustainable hydrogen. The project "HySecunda" aims to accelerate the development of suitable infrastructure and reduce production costs in order to establish South Africa as a major hydrogen producer for Germany and Europe. In addition, capacity building measures will be implemented to support the region in the use of hydrogen-based fuels for aviation.

Tasks of the Fraunhofer ISC in the project

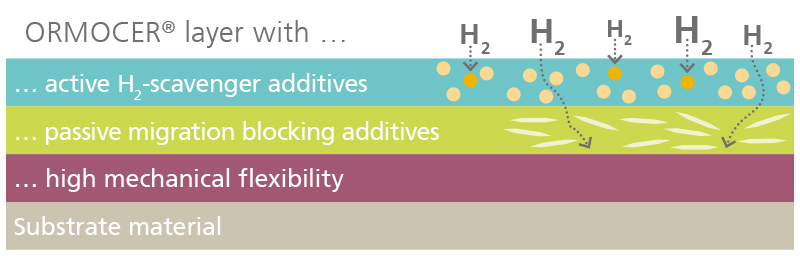

The Fraunhofer Institute for Silicate Research ISC is playing a key role in the HySecunda project, working, for example, on the development of barrier layers based on ORMOCER® and reliable hydrogen sensors. The aim is to make the production, storage, transport and use of green hydrogen efficient and safe. ORMOCER® barrier coatings are intended to extend the service life of containers used in water electrolysis.

The Fraunhofer ISC is also working on new material concepts for pressurized hydrogen storage tanks and on H2/O2-tight coatings for pipelines. Another focus is the simple, safe and immediate detection of hydrogen leaks. The institute is developing current-free sensors that can detect existing or past hydrogen leaks by a simple color change, without the need for additional aids.

Sensor modules are being developed to monitor hydrogen-carrying pipes and tanks for expansion stresses and early detection of material failures. This will allow better utilization of the service life of the materials used and reduce maintenance costs. For this purpose, flexible ultrasonic transducers are being developed that continuously monitor the pipes or tanks over a large area (~ m²) for incipient embrittlement or cracks.

Website »HySecunda«