Automation in the field of material development and production

Fraunhofer ISC offers its expertise in the automated production and testing of a wide range of materials.

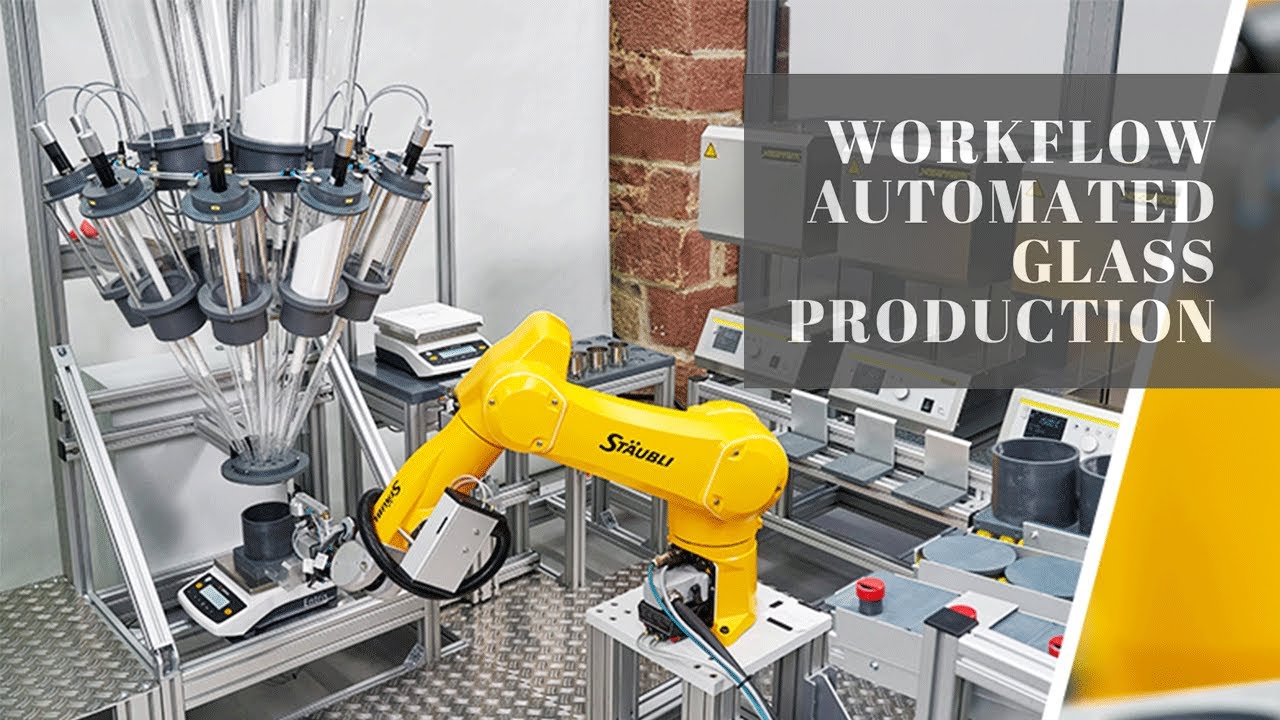

Interactive robotics implements process steps precisely, efficiently and with quality assurance. In combination with AI, quality assurance, cost savings and occupational safety are achieved. To this end, application-specific automated processes are established in various departments of the institute:

- At the Center of Device Development CeDeD, a globally unique high-throughput screening system for the fully automated production of specialty glasses was designed and built back in 2011.

- At the Translational Center for Regenerative Therapy TLC-RT, automated laboratories are being established in which materials and test systems are produced and substance tests are performed. Semi-automated solutions for 3D tissue culture and cell expansion are being developed. In more complex robot-assisted facilities, integrated, elaborate process sequences in the biological and chemical fields can be implemented. Thus, increased standardization and throughput can be achieved.

- The laboratory is the most important source of new data from experiments and measurements. Many procedures involve a great deal of work and require exact repetitions. In the area of Digital Transformation, we are therefore working on networked laboratory equipment and systems in order to automate work steps as far as possible. Work that can only be carried out by employees due to its complexity is supported by partially automated documentation. At the same time, the human being is still at the center of the orchestration of the complex overall process.