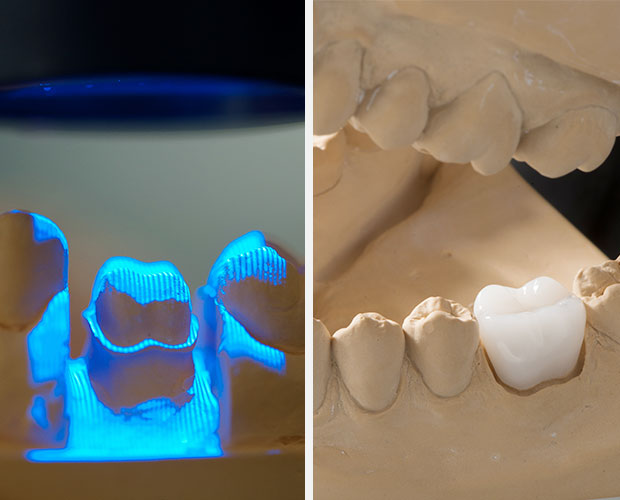

The Fraunhofer ISC has been setting standards for dental products in the fields of restoration and prophylaxis for decades

Contract research in cooperation with dental companies on hybrid polymers and glass ceramics developed and patented in-house has led to the launch of products such as ceram.x®, Admira®, Admira® Fusion, Admira® Fusion x-tra, Admira® Fusion x-base, SUPRINITY® PC, Celtra® and CEREC Tessera™. Our goal has always been to stay one step ahead of the current product generation.

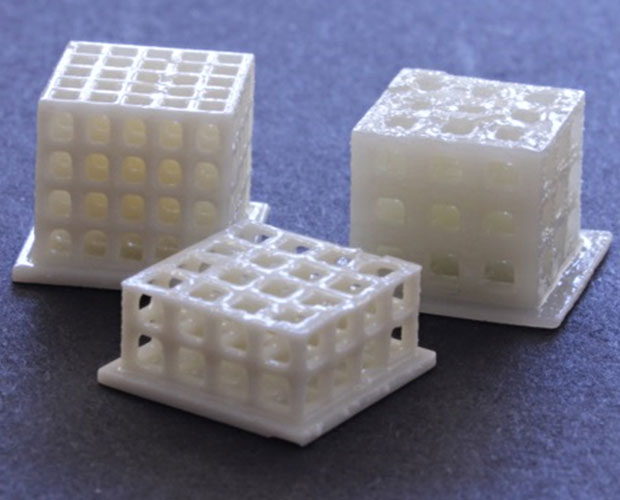

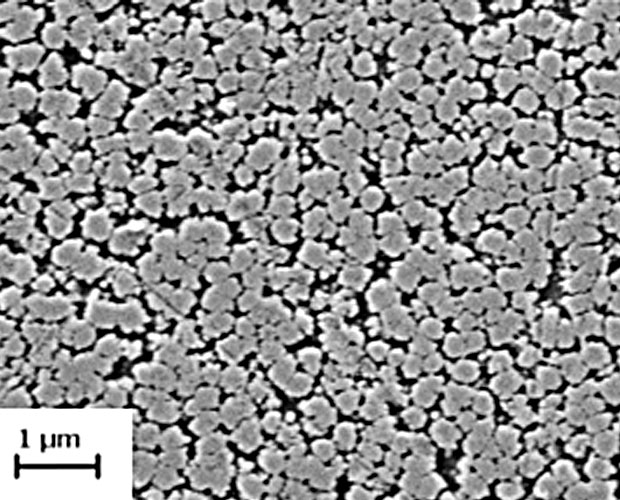

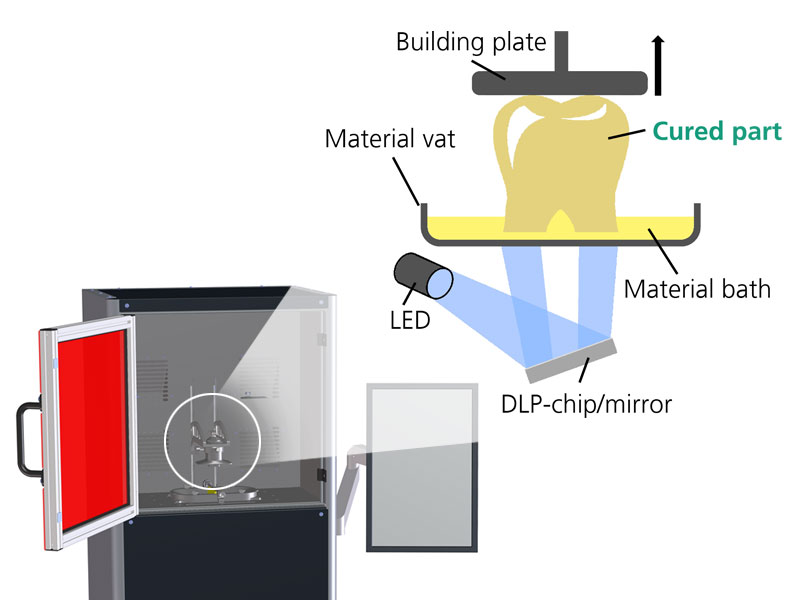

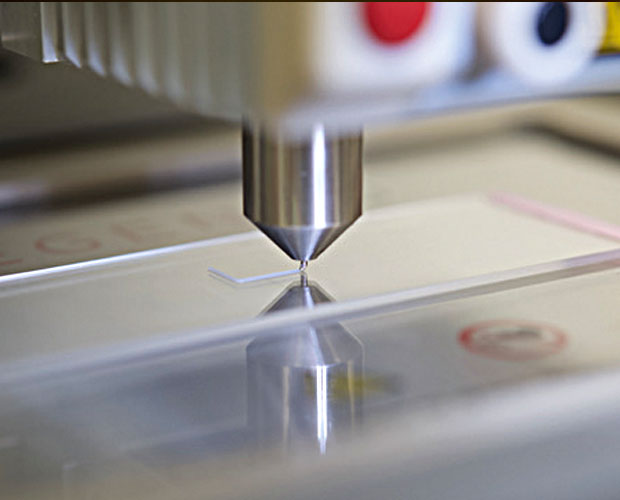

To achieve this, we use state-of-the-art synthesis processes to design our materials according to the desired requirements (e.g. biocompatible, biodegradable, PFAS-free or generally fluoride-free). In addition, our materials are chemically, physically and biologically characterized for specific applications and can be processed using various structuring and forming methods.

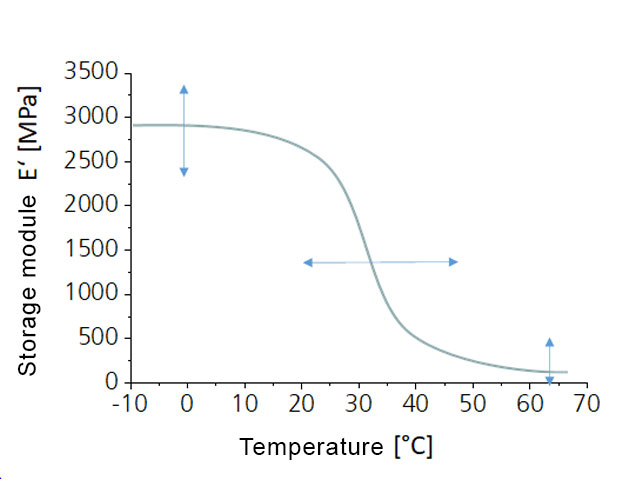

A logical next step was to leverage the unique properties of our dental materials in terms of biocompatibility, physiological resistance to biodegradation, shaping, processing, strength and elastomechanical properties for other biomedical applications.

Especially for complex requirements in the implant field (e.g. menisci, intervertebral discs, bioactive bone replacement, biomimetic implant systems), we can offer material solutions that are a decisive step ahead of the competition.